- HOME

- COMPANY

-

PRODUCTS

- Guardrail Machine

- Storage Rack Machine

- Slitting & Cut to length

- Silo Roll Forming Machine

- Pipe and Tube Machine

- Gutter & Downspout Machine

-

Door Series Machine

-

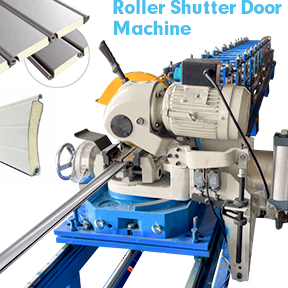

Australia Type Roller Shutter Door Roll Forming Machine

![Australia Saudi Type Roller Shutter Door Machine.jpg]()

-

Roller Shutter Door Nip Machine

![Roller Shutter Door Nip Machine.jpg]()

-

Roller Shutter Salt Roll Forming Machine

![Roller Shutter Lath Door Roll Forming Machine.jpg]()

-

PU Roller Shutter Door Making Machine

![cheap pu shutter door roll forming machine price .jpg]()

-

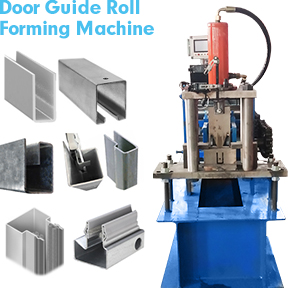

Door Guide Rail Roll Forming Machine

![Roller Shutter Door Guide Rail Roll Forming Machine.jpg]()

-

Roller Shutter Bottom Rail Machine

![Roller shuttert door Bottom lath roll forming machine manufacturer.jpg]()

-

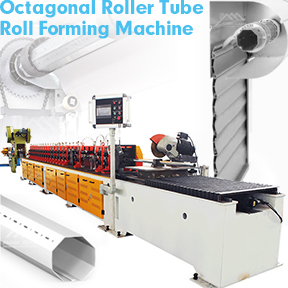

Octagonal Tube Roller Forming Machine

![Octagonal roller tube roll forming machine.jpg]()

-

Sectional Garage Door Roll Forming Machine

![Garage Door PU Sandwich Panel Machine.jpg]()

-

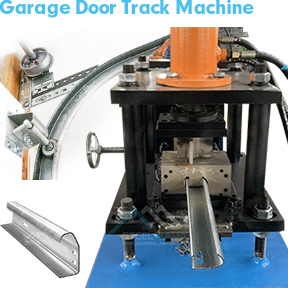

Garage Door Track Machine

![Garage Door Track Roll Forming Machine.jpg]()

-

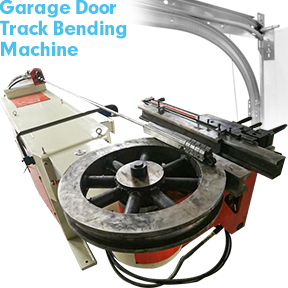

Garage Door Track Bending Machine

![Garage Door Track Bending Machine .jpg]()

-

Garage Door Struts Machine

![Garage Door Struts Roll Forming Machine.jpg]()

-

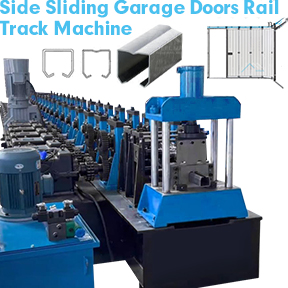

Sliding Garage Door Rail Machine

![Side Sliding Garage Doors Rail track channel Roll Forming Machine.jpg]()

-

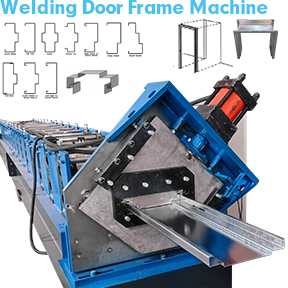

Welding Door Frame Machine

![Welding Steel Door Frame Roll Forming Machine Line.jpg]()

-

Self-joint Door Frame Machine

![Self Jointed Door Frame Rolll Forming Machine Line.jpg]()

-

Window Frame Machine

![Window Frame Machine.jpg]()

-

Australia Type Roller Shutter Door Roll Forming Machine

- Container Machine

- Cable Tray Machine

- CZU Purlin Machine

-

Stud and Track Machine

-

Stud and Track Machine

![C Stud and U Track roll forming machine.jpg]()

-

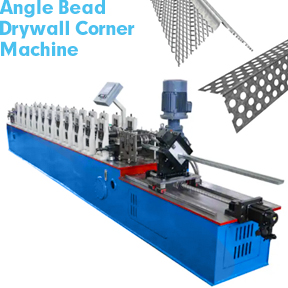

Angle Bead Machine

![Angle Bead Drywall Corner Machine.jpg]()

-

Light Steel Packing machine

![Automatic Stud and Track Packing Machine.jpg]()

-

Ceiling T Grid Machine

![Ceiling T Grid Roll Forming Machine.jpg]()

-

Furring Channel Machine

![Roll Forming Machine for Furring Ceiling System.jpg]()

-

Ceiling Spring Tee Machine

![Spring Tee Roll Forming Machine.jpg]()

-

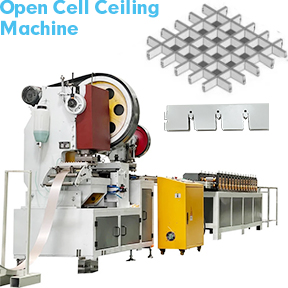

Open Cell Ceiling Grid Grilyato Machine

![Open Cell Ceiling System.jpg]()

-

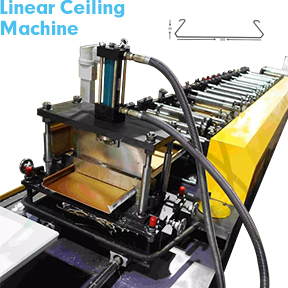

Strip Ceiling Machine

![Linear Roll Forming Machine.jpg]()

-

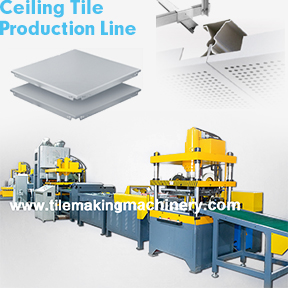

Ceiling Tile Production Line

![Ceiling Tile Production Line.jpg]()

-

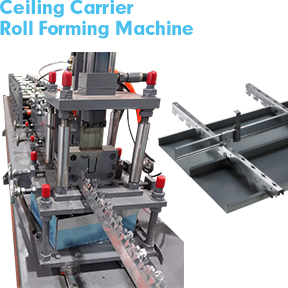

Ceiling Carrier Machine

![Ceiling Carrier Roll Forming Machine.jpg]()

-

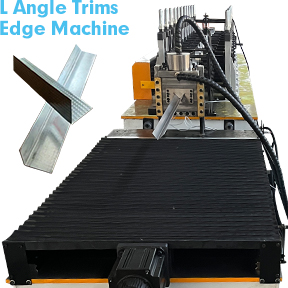

Ceiling Perimeter Angle And Trims Machine

![Angle Trims Edge Machine.jpg]()

-

Stud and Track Machine

- NEWS

- CONTACT