What is the purpose of providing gutter?

Your gutters are responsible for water management. During a storm, they effectively channel water flow from your roof, through the downspouts, and direct it to appropriate areas outside the home. Without a gutter system, your roof can pick up a bunch of leaves and other debris, causing water to stagnate and overflow.

| Are steel gutters good? Steel gutters are undoubtedly more durable and will keep its shape and profile much longer. . They're also harder to dent and hold up well in the heat. | ![hood_guard_for_roof_gutter hood_guard_for_roof_gutter]() | ![metal steel gutter metal steel gutter]() |

What is a gutter machine? What does a gutter machine do?

These machines allow you to manufacture your own gutters, which greatly reduces both the cost and time invested in each gutter job.

How do you run a gutter machine?

![gutter machine layout drawing gutter machine layout drawing]()

Han a gutter machine make downspouts?

Downspouts machine,They can handle mild steel, aluminum, or copper material and produce pipe at speeds up to 165 feet per minute.

Not only will buying a new gutter machine give you a competitive edge in your local market, but it will also help you control your own production and hang gutters as fast as you can make them. Understanding the price of a gutter machine and what to consider when choosing a new or used machine can help you select the right machine for your business now and in the future.

As manufacturers and sellers of innovative portable rollforming machinery, STEELMAMA knows how crucial it is for you to buy the best machines for your business needs.

How much gutter machines can cost

What to look for when buying a new gutter machine

Questions to ask yourself to help you buy the right machine

what to look for when buying a seamless gutter machine?

The best way to make sure you purchase the right seamless gutter machine is to be an educated consumer, as this equipment will be a major part of your business and help you generate profit.

So, when you go to purchase a new gutter machine, what should you look for?

You don’t necessarily want to buy the first new portable seamless gutter machine you look at. It’s important to compare and contrast attributes among machines you’re interested in. When looking at these gutter machines, check for the following:

Separate drive and forming rollers – The best rollforming machines, gutter or otherwise, tend to be ones with separate drive and forming rollers. Separating the two results in less stress on the metal because the rollers aren’t trying to form and drive the metal at the same time. Drive rollers are typically made of polyurethane or metal.

Warranties – Before you buy new equipment, always make sure you know about the manufacturer warranties on the machine or the various parts that are offered with the purchase.

Service, training, and availability of parts – Gutter machine operators never want their new machine to run into problems, but it’s critical that you know what to do and who to contact in the event your machine has issues. When looking at new machines, check with the manufacturer if they offer training at their facility or on-site for you and your employees to fully understand the ins and outs of how the machine works, maintenance, and safety practices. Also, check how quickly they’re typically able to provide service or replacement parts when a machine goes down.

Materials formed – Make sure the portable gutter machine you’re interested in will run the materials you plan to provide to your customers. For example, some machines don’t run copper or may be limited in material thicknesses and gauges.

Gutter size – If you know the majority of your clients will want a 5” gutter, you might be fine just purchasing the one machine size. However, if you want to offer both 5” and 6”, a combo gutter machine may be your best option. Knowing what size of gutter is popular in your area will help you choose the right machine for your business.

Gutter profile – Depending on the number of profile options you want to provide to your customers to choose from (i.e. back flanges, hooks, etc.), make sure the machines you’re looking at are able to rollform each variation. It’s also important to know what styles are popular in your region, whether it’s k-style, box, or otherwise.

Machine length – The longer the machine, the higher the quality of the finished product. This is due to the machine having more spread out forming stations used to gradually form the metal, which reduces stresses inflicted on the materials during the rollforming process.

Push-button controls vs. drum switch – For controlling the machine, push-button controls are considered the better option, as they are easier and more efficient to use.

Availability of length control – If you’re looking for the machine to automatically stop at a specified length, ensure you get a rollformer with a computer controller that allows this function.

Questions to Ask Yourself Before Buying a Gutter Machine

If you’re still unsure whether to invest in a new or used portable gutter machine, there are some things you can do to help steer you in the right direction. Start by asking yourself some of the following questions to better gauge yourself and your business needs, which can help you determine new vs. used machines and if any add-ons are necessary to buy:

Can I afford a new machine? Or can I only afford one that is used?

If I desire a new gutter machine, but don’t have the cash at the moment, can I get approved for leasing or financing?

Have I been having an issue with or am I at the mercy of a gutter manufacturer/supplier?

Do I want to focus on producing gutters, hanging/installing gutters, or both?

What profile and size options do I want to offer to my customers?

Does my business have a skilled employee who can and will run and maintain the gutter machine?

Do I live in an area where my gutter machine would be affected by extreme weather conditions (cold or hot) if it wasn’t enclosed?

Starting a gutter business is no easy task, and buying a gutter machine is no small investment. New business owners looking to get into the gutter business should keep these things in mind before buying a gutter machine.

1. Will you offer gutter installation and fabrication at first?

Experienced gutter installers know that not all gutter companies sell the same products and services. If you don't have the initial funds to purchase a gutter machine, your business may start out as an installation-only service.

Your company is responsible for finding customers, creating estimates, and installing the gutters. There are a number of companies that you can hire to cut gutters to your specifications on-site. Just add your labor and other expenses and you have a service business that requires very little start-up cash.

2. Determine the right time to buy a gutter machine

If and when your business does have the funds available to buy a seamless gutter machine, you are able to go from buying "premade" gutters to producing them at a fraction of the cost.If your business plan involves selling to construction and roofing companies, making connections within the industry is much easier when you have the ability to fabricate gutters. Your business may choose to only fabricate seamless gutters, but having workers available to offer fabrication and installation is ideal.

3. Analyze the market for investment level

Depending on the scale of your business and if you plan to offer services to construction, residential, and commercial customers, you may require more than one machine. This means there will be a much higher initial investment, so it is worth considering how you plan to enter the market.

Are there enough residential and commercial business opportunities in your area to justify having more than one gutter machine? Or will your business focus on one key market at first and scale in the future based on demand?

4. Consider all start-up costs

While a gutter machine may be one of the biggest early investments for your business, there are a number of other start-up costs to consider, including:

For insurance and tax purposes, it is important to register your business, most commonly as a Limited Liability Company (LLC). This is a fairly inexpensive, but important, first step in starting your gutter business.

How Much Does a Gutter Machine Cost In 2002?

As manufacturers and sellers of innovative portable rollforming machinery, STEELMAMA knows how crucial it is for you to buy the best machines for your business needs.

Please note that each machine’s price will increase depending on your selection of optional features and equipment.Contact STEELMAMA and talk to our Account Managers to discuss the machine configuration that will work best for you.

Reach out to any of our Account Managers for more information about the gutter machines available, or to help you find the best machine configuration for your business.

![steel cold roll forming machine-steelmama steel cold roll forming machine-steelmama]()

|

About SteelmamaSTEELMAMA was founded in 2009. Since its inception, STEELMAMA has always uphold the "create a first-class enterprise, first-class talents, first class contribution" vision, to create a well-known "STEELMAMA" brand. STEELMAMA’s main business is to "project" as the theme of “CHINA STEEL AGENT SERVICE”, leading products for steel profile machinery include roll forming machine, press brake bending machine and other steel processing machinery, and steel coil include PPGI coil, GI coil, Aluminium coil, Alu-zinc coil and steel strips and plates, also steel building material like metal roofing sheet, purlin sections, H steel, welding mill tube and some hardwares to be global brand.

We design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction, and manufacturing industries. Our goal is to provide flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experiences.

Your success is our success

|

|

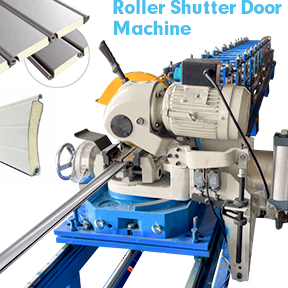

![Australia Saudi Type Roller Shutter Door Machine.jpg]()

![Roller Shutter Door Nip Machine.jpg]()

![Roller Shutter Lath Door Roll Forming Machine.jpg]()

![cheap pu shutter door roll forming machine price .jpg]()

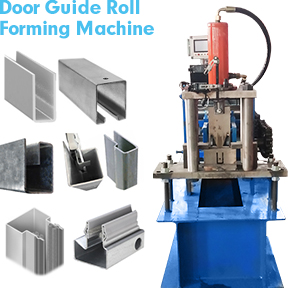

![Roller Shutter Door Guide Rail Roll Forming Machine.jpg]()

![Roller shuttert door Bottom lath roll forming machine manufacturer.jpg]()

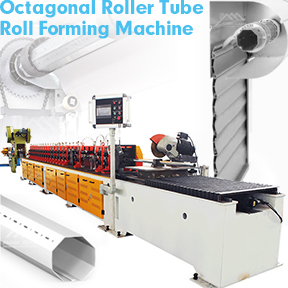

![Octagonal roller tube roll forming machine.jpg]()

![Garage Door PU Sandwich Panel Machine.jpg]()

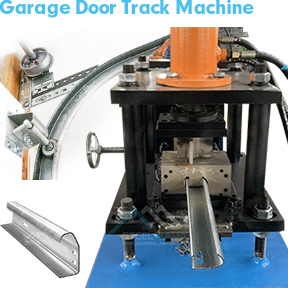

![Garage Door Track Roll Forming Machine.jpg]()

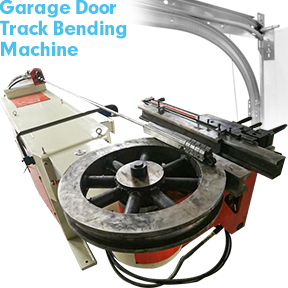

![Garage Door Track Bending Machine .jpg]()

![Garage Door Struts Roll Forming Machine.jpg]()

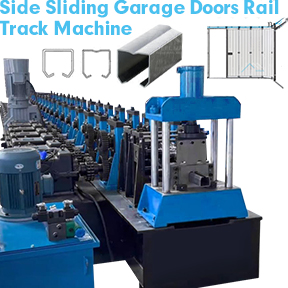

![Side Sliding Garage Doors Rail track channel Roll Forming Machine.jpg]()

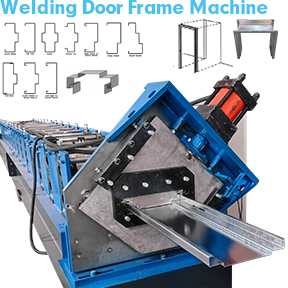

![Welding Steel Door Frame Roll Forming Machine Line.jpg]()

![Self Jointed Door Frame Rolll Forming Machine Line.jpg]()

![Window Frame Machine.jpg]()

![C Stud and U Track roll forming machine.jpg]()

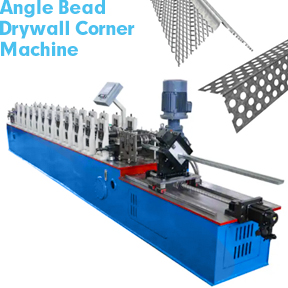

![Angle Bead Drywall Corner Machine.jpg]()

![Automatic Stud and Track Packing Machine.jpg]()

![Ceiling T Grid Roll Forming Machine.jpg]()

![Roll Forming Machine for Furring Ceiling System.jpg]()

![Spring Tee Roll Forming Machine.jpg]()

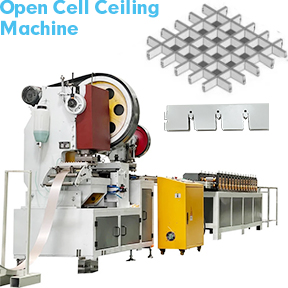

![Open Cell Ceiling System.jpg]()

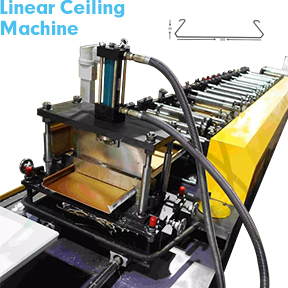

![Linear Roll Forming Machine.jpg]()

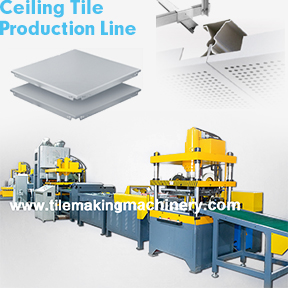

![Ceiling Tile Production Line.jpg]()

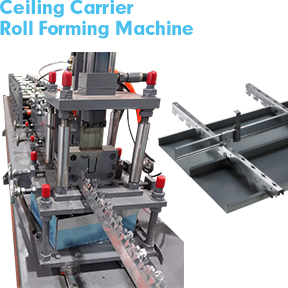

![Ceiling Carrier Roll Forming Machine.jpg]()

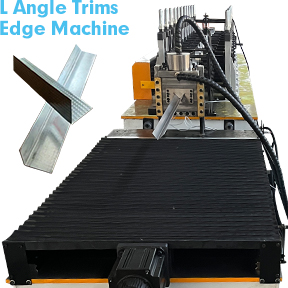

![Angle Trims Edge Machine.jpg]()