In the world of modern metal fabrication, efficiency, precision, and versatility are critical for staying competitive. For businesses involved in manufacturing structural components, furniture, automotive frames, or industrial assemblies, the square tube roll forming machine has become an indispensable asset. This specialized equipment transforms metal coils into precise, high-strength square and rectangular tubing through a continuous cold-forming process. But what specific benefits does it offer over traditional manufacturing methods? Let's explore the key advantages that make investing in a square tube roll forming machine a strategic decision for your production line.

![square tube forming machine square tube forming machine]()

1. Exceptional Production Efficiency & High Speed

A primary advantage of a square tube roll forming machine is its remarkable high production efficiency. Operating as a continuous, automated process, it can produce square tubing at significantly faster rates compared to batch processes like welding individual sides. This seamless operation from coil to cut-off minimizes downtime, maximizing output and allowing you to meet large-volume orders and tight deadlines with ease.

2. Superior Consistency and Unmatched Accuracy

The roll forming process ensures every meter of tubing produced is identical. Each strip of metal passes through a series of precisely engineered roll forming stations, which gradually shape it into the final profile. This results in excellent dimensional accuracy with consistent wall thickness, straightness, and corner radii. Such uniformity is crucial for automated assembly lines and ensures the structural integrity and reliability of your final products.

3. Significant Material & Cost Savings

This machinery promotes remarkable material savings and reduced operational costs. The process generates very little scrap, especially when compared to methods involving cutting and welding. Furthermore, automation reduces direct labor costs and minimizes human error. The ability to use raw coil stock, which is often more cost-effective than pre-cut sheets, also contributes to a lower overall cost per unit for the finished hollow structural sections (HSS).

![Square Tube Machine factory Square Tube Machine factory]()

4. Enhanced Strength and Product Quality

The cold-forming work-hardens the metal at the bends, enhancing the strength of the corners without adding weight. The resulting square tube or rectangular tube has a clean, weld-free appearance with superior surface finish. For applications requiring welding, the consistent geometry allows for faster and higher-quality downstream welding operations, improving the overall final product quality.

5. Remarkable Flexibility and Customization

Modern square tube roll forming machines offer impressive operational flexibility. By changing the forming rolls and adjusting the machine settings, a single production line can manufacture tubes of different sizes, thicknesses, and even similar profiles like rectangular tubing. This flexibility allows manufacturers to respond quickly to custom orders and market demands without requiring separate, dedicated lines for each profile.

6. Integrated Manufacturing Capabilities

A complete tube mill line often integrates additional processes, showcasing advanced integrated manufacturing capabilities. This can include in-line pre-punching of holes, notching, or embossing before the forming stage, as well as automatic welding (for closed profiles) and precise flying cut-off for length accuracy. This creates a streamlined, single-pass production system that boosts overall productivity.

![Square Tube cold roll forming machine Square Tube cold roll forming machine]()

Conclusion: A Foundational Investment for Growth

In summary, the advantages of a square tube roll forming machine—encompassing high production efficiency, consistent accuracy, significant cost savings, enhanced strength, and operational flexibility—make it a cornerstone of profitable and competitive metal fabrication. It transforms the production of hollow structural sections from a challenging task into a smooth, reliable, and highly efficient process.

![Australia Saudi Type Roller Shutter Door Machine.jpg]()

![Roller Shutter Door Nip Machine.jpg]()

![Roller Shutter Lath Door Roll Forming Machine.jpg]()

![cheap pu shutter door roll forming machine price .jpg]()

![Roller Shutter Door Guide Rail Roll Forming Machine.jpg]()

![Roller shuttert door Bottom lath roll forming machine manufacturer.jpg]()

![Octagonal roller tube roll forming machine.jpg]()

![Garage Door PU Sandwich Panel Machine.jpg]()

![Garage Door Track Roll Forming Machine.jpg]()

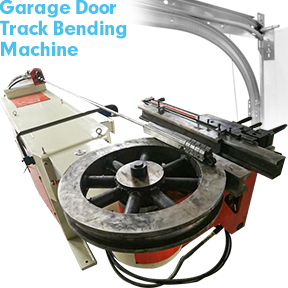

![Garage Door Track Bending Machine .jpg]()

![Garage Door Struts Roll Forming Machine.jpg]()

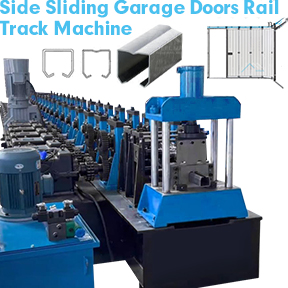

![Side Sliding Garage Doors Rail track channel Roll Forming Machine.jpg]()

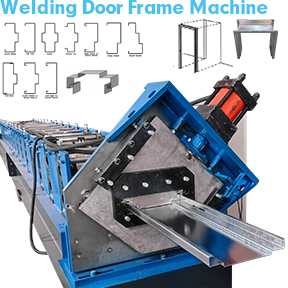

![Welding Steel Door Frame Roll Forming Machine Line.jpg]()

![Self Jointed Door Frame Rolll Forming Machine Line.jpg]()

![Window Frame Machine.jpg]()

![C Stud and U Track roll forming machine.jpg]()

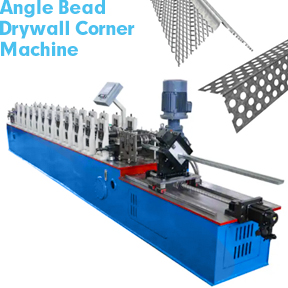

![Angle Bead Drywall Corner Machine.jpg]()

![Automatic Stud and Track Packing Machine.jpg]()

![Ceiling T Grid Roll Forming Machine.jpg]()

![Roll Forming Machine for Furring Ceiling System.jpg]()

![Spring Tee Roll Forming Machine.jpg]()

![Open Cell Ceiling System.jpg]()

![Linear Roll Forming Machine.jpg]()

![Ceiling Tile Production Line.jpg]()

![Ceiling Carrier Roll Forming Machine.jpg]()

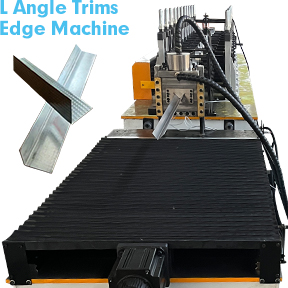

![Angle Trims Edge Machine.jpg]()