Unlock Efficiency and Profit: Your Ultimate Guide to the Shutter Door Machine

Introduction

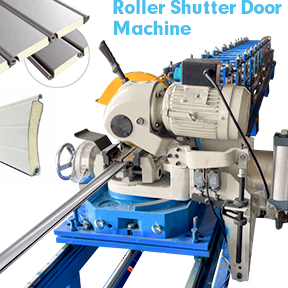

Rolling shutter doors are a cornerstone of modern infrastructure, providing security, durability, and space-saving solutions for warehouses, factories, garages, and commercial establishments. Behind every high-quality shutter door is a precision-engineered Rolling Shutter Machine Investing in the right Door Making Machine isn't just a purchase; it's a strategic decision to boost your production capacity, enhance product quality, and maximize your profitability.

A Euro Type Shutter Door Roll Forming Machine is a specialized roll-forming system designed to continuously shape coils of steel, aluminum, or other metals into the interlocking slats and components that make up a rolling shutter door. This automated equipment is the heart of any shutter door manufacturing business, transforming raw materials into finished, market-ready products with consistent precision and speed.

In a competitive market, the quality of your doors starts with the quality of your machinery. Here’s why choosing the right machine is critical for your success:

Unmatched Production Efficiency: Automate your production line and produce shutter door slats at an incredible speed, meeting large orders and tight deadlines with ease.

Consistent, Flawless Quality: A precision auto shutter door machine ensures every slat has the exact same profile, dimensions, and finish. This eliminates defects and builds your reputation for reliability.

Remarkable Versatility: Modern Australia Type Shutter Door Machines can be configured to produce a wide range of profiles, sizes, and designs, allowing you to cater to diverse customer demands with a single investment.

Significant Cost Reduction: By automating the forming process, you drastically reduce labor costs, material waste, and the need for rework, directly improving your bottom line.

Competitive Edge: With the ability to produce superior doors faster and more cost-effectively, you can outpace competitors and capture a larger market share.

![Euro Type Shutter Door Roll Forming Machine Euro Type Shutter Door Roll Forming Machine]()

Door Making Machine

How to Choose the Right Auto Shutter Door Machine for Your Business

Selecting the perfect machine requires careful consideration of your specific needs. Ask yourself these key questions:

Production Volume: Are you a startup or an established manufacturer? Your required output will determine the machine's speed and level of automation.

Material Type: Will you be working primarily with steel, aluminum, or galvanized iron? The machine must be compatible with your chosen material's thickness and strength.

Profile Variety: Do you need to produce multiple slat profiles? Look for a metal shutter door roll forming machine that offers quick and easy tooling changes for maximum flexibility.

Level of Automation: From basic manual models to fully automated lines with PLC control and automatic cutting, choose the technology that matches your budget and operational goals.

Space and Power Requirements: Ensure your workshop can accommodate the shutter door rolling machine's footprint and power supply (electrical or hydraulic).

At steelmama, we don't just sell machines; we deliver robust, turn-key manufacturing solutions. Our shutter door machines are engineered for excellence, built to last, and designed to be your partner in growth.

Robust Construction & Durability: Built with high-grade components to withstand rigorous, continuous operation.

Precision Engineering: Guaranteeing perfect profiles and smooth, interlocking slats every time.

User-Friendly Operation: Intuitive controls and comprehensive training make it easy for your team to operate efficiently.

Expert Technical Support: We provide lifelong after-sales service, technical support, and readily available spare parts.

Customizable Solutions: We work with you to configure a machine that perfectly fits your unique production requirements.

The right Metal Shutter Door Roll Forming Machine is the most critical investment you will make for the future of your business. It’s the key to unlocking new levels of productivity, quality, and profit.

Don't settle for outdated or inefficient methods. Take the first step towards manufacturing excellence today.

![Australia Saudi Type Roller Shutter Door Machine.jpg]()

![Roller Shutter Door Nip Machine.jpg]()

![Roller Shutter Lath Door Roll Forming Machine.jpg]()

![cheap pu shutter door roll forming machine price .jpg]()

![Roller Shutter Door Guide Rail Roll Forming Machine.jpg]()

![Roller shuttert door Bottom lath roll forming machine manufacturer.jpg]()

![Octagonal roller tube roll forming machine.jpg]()

![Garage Door PU Sandwich Panel Machine.jpg]()

![Garage Door Track Roll Forming Machine.jpg]()

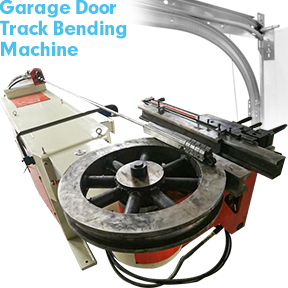

![Garage Door Track Bending Machine .jpg]()

![Garage Door Struts Roll Forming Machine.jpg]()

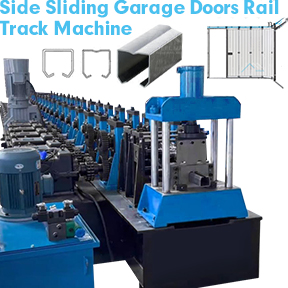

![Side Sliding Garage Doors Rail track channel Roll Forming Machine.jpg]()

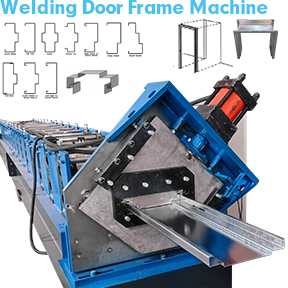

![Welding Steel Door Frame Roll Forming Machine Line.jpg]()

![Self Jointed Door Frame Rolll Forming Machine Line.jpg]()

![Window Frame Machine.jpg]()

![C Stud and U Track roll forming machine.jpg]()

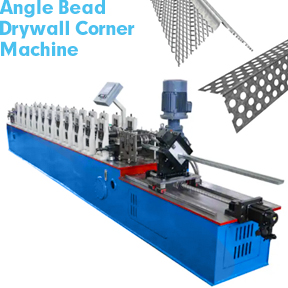

![Angle Bead Drywall Corner Machine.jpg]()

![Automatic Stud and Track Packing Machine.jpg]()

![Ceiling T Grid Roll Forming Machine.jpg]()

![Roll Forming Machine for Furring Ceiling System.jpg]()

![Spring Tee Roll Forming Machine.jpg]()

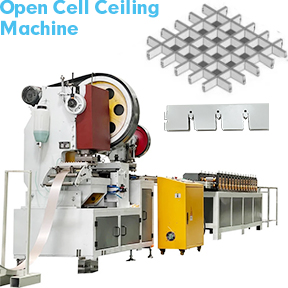

![Open Cell Ceiling System.jpg]()

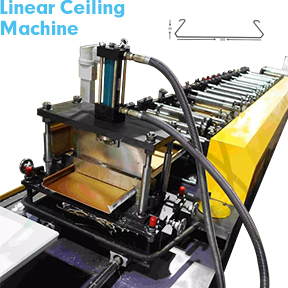

![Linear Roll Forming Machine.jpg]()

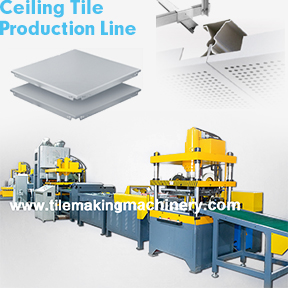

![Ceiling Tile Production Line.jpg]()

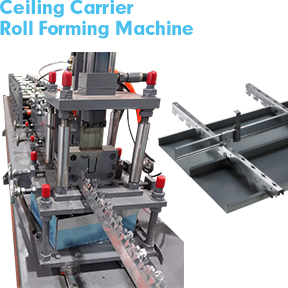

![Ceiling Carrier Roll Forming Machine.jpg]()

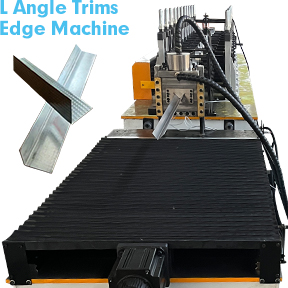

![Angle Trims Edge Machine.jpg]()